GP Graders is a multi-award winning world leader in fruit grading and sorting technology. GP Graders have been manufacturing machinery for the fresh produce industry since 1963 to meet the needs of fruit growers and packers around the globe.

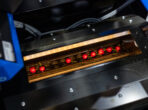

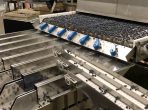

We prioritize turn-key solutions and provide a complete range of sorting and grading machinery. We emphasize building and designing products that are fast, accurate, and gentle with your produce. Combining the very latest advances in technology with precision engineering, our machinery increases the competitiveness and profitability of our customers.

GP Graders have a well-earned reputation for being specialists in grading and sorting technology for cherries, blueberries, small tomatoes and stone fruits. Our focus on small fruit grading for over 60 years has ensured we have the expert knowledge to improve packhouse operations and a vast list of satisfied, long-standing customers is a testament to the success we’ve created with our partners.

GP Graders are proud to be Australian owned and operated.